Our innovation is at the forefront to work on customers complex requirements. Development parts evolve through various iterations, we can quickly produce new soft tooling and machining activities to accommodate the necessary design We understand every innovation need to go through proto typing and testing. Hence, we support all our customers with low cost, soft tooling and small quantity proto parts to help them validate their design and functionality.With an in-house tool room, laser welding and CAD capabilities, and a skilled, experienced staff, we can guarantee that every prototype samples customer needs can be executed in minimum time.

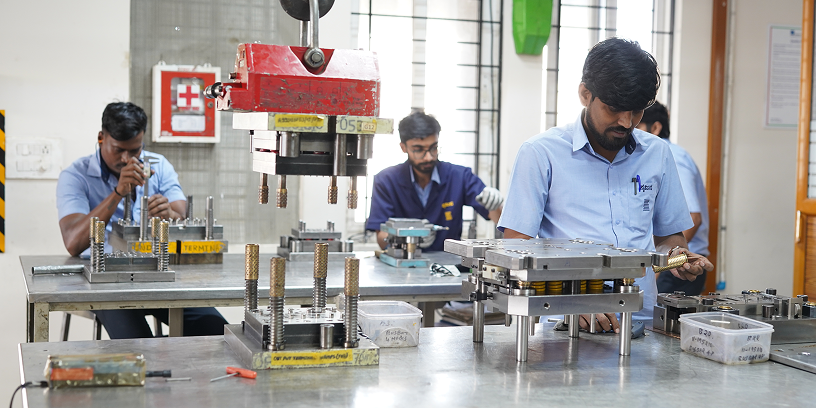

Srujana has developed in-house capability with the team, infrastructure and tools for production of soft and small batch proto order. At Srujana, we provide high-quality prototyping, rapid tooling, and low-volume manufacturing services to support your product development needs. Our team of engineers works with you to make your product ideas a reality through different manufacturing technologies.

To support proto tooling as well regular production assemblies, we have completely equipped with the latest state of Technology Laserwelding equipment and testing lab.

Why Choose Us

Precision-Driven Engineering - Every component we produce reflects our commitment to accuracy and durability, ensuring superior performance in critical industrial applications.

Custom Solutions, Every Time - From one-off prototypes to high-volume production, our solutions are tailored to meet your exact technical and functional requirements.

Timely Deliveries - We know time is money. Our optimized processes and experienced team ensure reliable delivery without delays.

Quality Without Exception - Rigorous quality checks and ISO-certified processes ensure that every product meets the highest standards, every time.

Frequently asked questions

Brass, Copper, Nickel

Our over 3 decades of financial stability provide us the ability to carry the raw material inventory ahead of customer's needs. This approach allows for smaller, less costly inventory investments without jeopardizing scheduled delivery requirements.

Yes we also do stamping of preplated materials, and we also have been working with some of the best and reliable partners for plating of materials.